|

|

|

Home

About Us

Products

Applications

Gallery

Contact

|

|

|

|

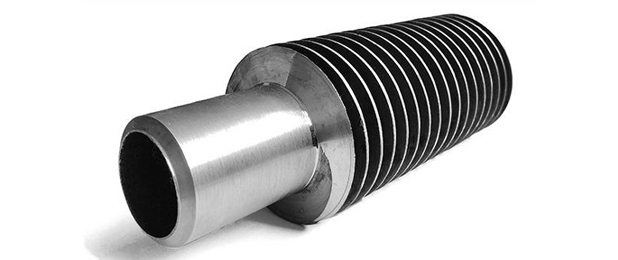

Integral High Fin Tubes

|

Product Specification

|

| Tube OD: |

32mm to 51mm |

1 1/4" to 2"(NPS) |

| Tube WT: |

4.0mm to 8.0mm |

0.16" to 0.31" |

| Tube Length: |

20000mm max |

66ft max |

| Fin Thickness: |

1.6mm to 2.0mm |

0.063" to 0.079" |

| Fin Height: |

3mm to 15mm |

0.118" to 0.591" |

| Fin Pitch: |

50FPM to 125FPM |

2FPI to 5FPI |

| Fin Type: |

Integral High |

|

Material

|

| Tube Material: |

- Carbon Steel: most common grades are SA179, SA192, SA210A1, SA210C, SA106Gr.B

- Stainless Steel: most common grades are TP304, TP316, TP321, TP347, 2205

- Alloy Steel: most common grades are T5, T9, T11, T12, T22, T91, P5, P9, P11, P12, P22, P91

- Copper: most common grades are UNS12200, 14200, 70600, CuNi70/30, CuNi90/10

|

* This table is used as a general guide to our capabilities, please contact us for any other customized cases.

Fabrication Process

The fins are rolled out from the wall of the tubes and hence are integral with the tube. As the fins are formed from the base tube by rolling out material from its wall, the wall thickness under the finned section is reduced compared to the wall thickness at plain ends. These fin tubes can be manufactured from most tubular materials and the hardness of the material usually determines the finning code or fin profile. The harder materials such as Nickel Alloys, Stainless Steel, Titanium are supplied with higher density (i.e. 26, 28, 30 FPI). This shallow profile reduces the work hardening of the material and helps to eliminate the possibility of root fin cracking.

Whereas, softer materials like Carbon Steel, Copper, and Copper Alloys are supplied with deeper profile giving a lower fin density (i.e. 16 or 19 FPl). These tubes can also be supplied with intermediate plain landing as well as U bent, where U bend portion can be finned or un-finned.

Production Capacity

Total four finning lines, monthly production capacity is 85000 meters in total.

Codes and Standards

As per drawings and client's Requirements

|

|

Add: Jingang Road, Free Trade Zone, Zhangjiagang, Suzhou, Jiangsu, China

Tel: +86-512-58702003 | Email: sales@tubemfg.com

|