|

|

|

Home

About Us

Products

Applications

Gallery

Contact

|

|

|

|

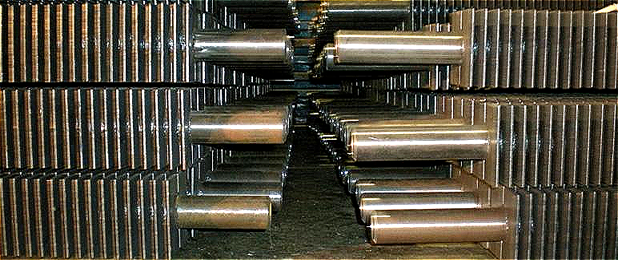

H/HH Finned Tubes

|

Product Specification

|

| Tube OD: |

25mm to 73mm |

1/2" to 2 1/2" (NPS) |

| Tube WT: |

3.0mm to 6.0mm |

0.118" to 0.236" |

| Tube Length: |

20000mm max |

66ft max |

| Fin Thickness: |

1.5mm to 4.0mm |

0.06" to 0.158" |

| Fin Height: |

25mm to 45mm |

0.99" to 1.78" |

| Fin Length: |

50mm to 250mm |

1.98" to 9.9" |

| Fin Pitch: |

20FPM to 117FPM |

1FPI to 3FPI |

| Fin Type: |

H, HH |

|

Material

|

| Tube Material: |

- Carbon Steel: most common grade is SA106 Gr.B

- Stainless Steel: most common grades are TP304, TP316, TP321, TP347, 2205

- Alloy Steel: most common grades are T5, T9, T11, T12, T22, T91, P5, P9, P11, P12, P22, P91

|

| Fin Material: |

- Carbon Steel: most common grade is Q235B

- Stainless Steel: most common grades are TP304, TP316, TP321, TP347, 2205

- Alloy Steel: most common grade is 12Cr1MoVG

|

* This table is used as a general guide to our capabilities, please contact us for any other customized cases.

Welding Process

Square finned tube can be manufactured in almost any shape or size. This style of fin is commonly referred to as "Square Fin" or "Plate Fin". Although any shape is possible, square and round are the norm. An electric current is applied by contacts on the square fins (by using special contours) and tube and the resistance in this circuit produces the heat necessary for welding. Maximum resistance and therefore maximum heating occur at the interface between the fin and the tube. Pressure to forge the square fins and the tube together at the point of maximum heating is applied by various forms of tooling. These resistance welding processes produce a strong metallurgical bond between the fin and the tube while minimizing the heat affected zone (HAZ) in the tube.

Production Capacity

Total six medium frequency welded H/HH type finning lines, monthly production capacity is 1500 tons in total.

Codes and Standards

As per drawings and client's Requirements

Surface Treatment and Protection

Each tube except stainless material will be polished by polishing machine to near bright condition before welding.

After welding, the finned tubes will be coated for transportation and site storage purpose, normally the coat will provide a period of 3 months prevention, any other coating material for longer prevention is also available as per clients' requirements.

|

|

Add: Jingang Road, Free Trade Zone, Zhangjiagang, Suzhou, Jiangsu, China

Tel: +86-512-58702003 | Email: sales@tubemfg.com

|